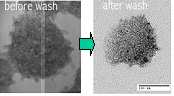

Washing

the mixed composites generates meso-porous particles

Washing

the mixed composites generates meso-porous particlesMicroporous inorganic solids such as zeolites have found wide application including molecular sieving & chemical absorption with the target of gas sensor because of their large internal surface area. However, because of the limitation of pore size to typically < 1.5nm, new synthetic methods have been investigated to extend the range of available pore size. Such methods include using templates of surfactant liquid and colloidal crystals to produce meso-porous materials with pore diameters between 2 and 10nm.

Although these new methods was successfully extend the porosity of zeolite-type materials, they may have essentially unavoidable problems of requiring a secondary hydrothermal process to remove the template materials. During the process, the very narrow capillaries composing porous structure are easily collapsed. Furthermore, most templating procedures in batch reactor operations require tediously time-consuming jobs, one-time-only use of the expensive template materials & solvents make their economical applications difficult.

Here, I would introduce a novel & most economically applicable method using salt as templates, which advantage was originally confirmed by my former college, Prof. Michael R. Zachariah at U of Minnesota, recently moved to U of Maryland. Based on his results, I will spread it out to the different matials. The next figure shows an example of our nanoporous materials made by the method.

Washing

the mixed composites generates meso-porous particles

Washing

the mixed composites generates meso-porous particles